WE OFFER CUSTOMERS WHAT THEY NEED

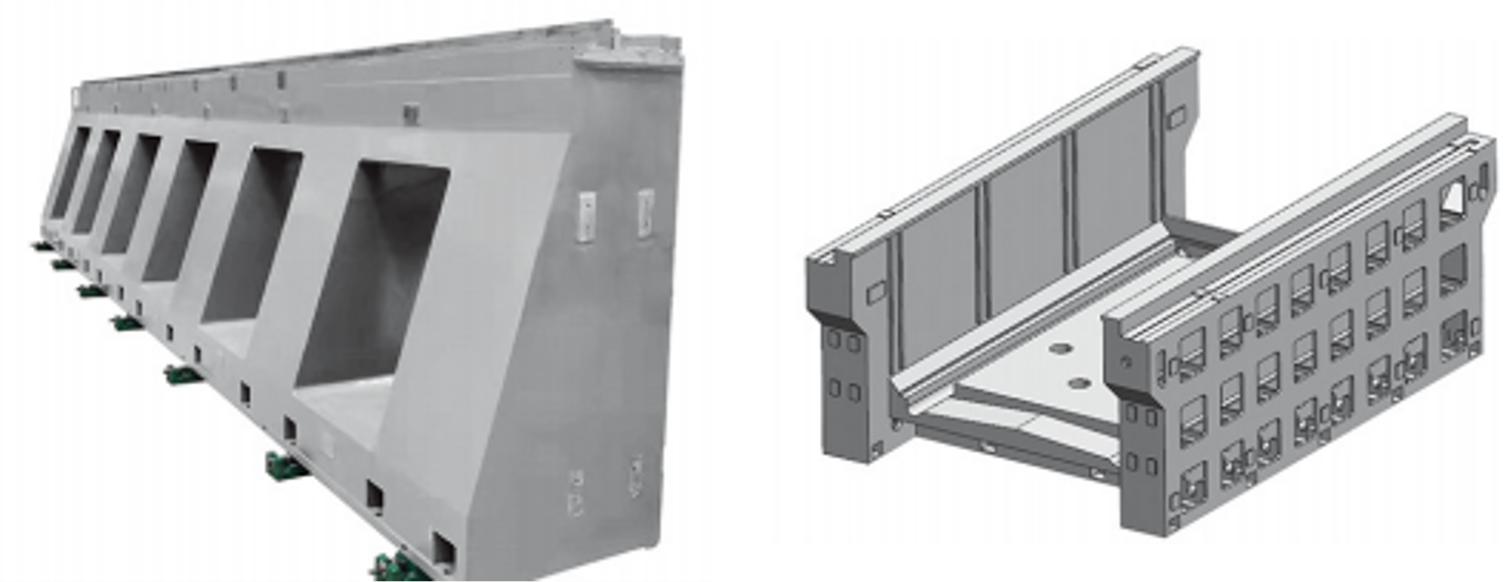

The comprehensive project solution from design proposal, selection of suitable material and production technology, to production, inspection and delivery to the destination.

WE OFFER CUSTOMERS WHAT THEY NEED

The comprehensive project solution from design proposal, selection of suitable material and production technology, to production, inspection and delivery to the destination.

MATERIAL IS ALPHA AND OMEGA OF EVERY CASTING.

Properly chosen material is a guarantee that the casting will fulfil its function in any situation.

The cast iron with nodular graphite, which is characterized by high tensile strength, hardness and ductility.

| DIN EN 1561 | RM MIN (N/MM2) | HBB MAX (BRINELL) |

|---|---|---|

| EN-GJL-400-15 | 400 | 200 |

| EN-GJL-4000-180-LT | 400 | 140-200 |

| EN-GJL-500-7 | 500 | 230 |

| EN-GJL-600-3 | 600 | 270 |

| EN-GJL-700-2 | 700 | 300 |

The cast iron with flake graphite, which is characterized by relatively high strength and hardness.

| DIN EN 1561 | RM MIN (N/MM2) | HBB MAX (BRINELL) |

|---|---|---|

| EN-GJL-200 | 200 | 220 |

| EN-GJL-250 | 250 | 240 |

| EN-GJL-300 | 300 | 260 |

This is a special bainitic ductile iron, which is characterized by very favourable strength, ductility, dynamic strength, and abrasion resistance. ADI cast iron with its mechanical properties is very similar to cast steel.

| DIN EN 1564 | RM (N/MM) |

|---|---|

| EN-GJL-800-10 | 800 |

| EN-GJL-1400-1 | 1400 |

We offer materials such as steel for refining, heat-resistant steel. Based on the required characteristics of the manufactured part, we choose a suitable type of steel, which differ from each orther in chemical properities. We can provide cast steel castings from 5 kg to 10 000 Kg according to drawings and material specifications.

We offer Lost Foam Casting as an innovative and cost attractive alternative to the traditional foundry process.

Advantages of using Lost Foam technology:

Lost Foam technology uses polystyrene models (EPS) that are filled entirely in the casting mould. The liquid metal poured into the mould fills the cavity and also burns the model.

This method is in many cases much more economical compared to the traditional method, which uses wooden models.

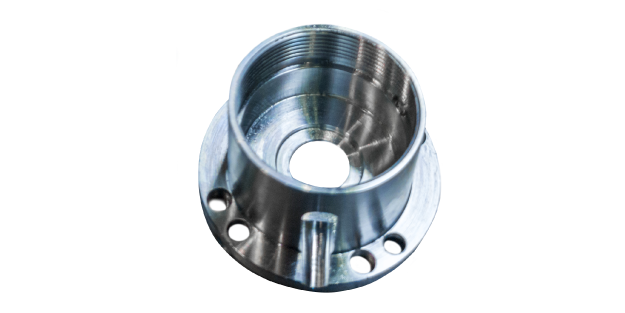

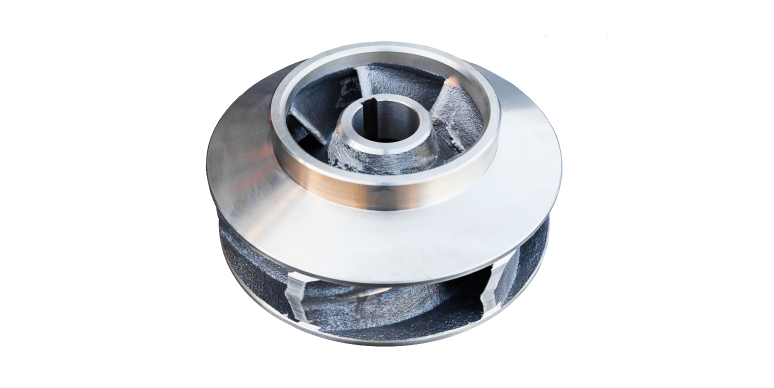

We supply castings casted in sand mixtures, as well as in metal moulds, by gravity, low pressure, high pressure and even precision castings on a meltable model.

All types of aluminium alloys for a wide range of industrial applications. We supply sand castings, precision castings from wax patterns, from cocci, from low and high pressure technology and castings from squeez technology. We provide units of pieces and also ten thousand piece batches ranging in weight from 0.1kg to 10,000kg. Surface treatments with wet or powder paint, anodization (elox), as well as final machining or pressure testing.

| Alloy | State | Rm - (MPa) | Rp0.2 0.2% (MPa) | Ductility (%) | Hadrness (HBW) |

|---|---|---|---|---|---|

| AlSi7Mg0,3 EN AC-42100 A356.0 | T6 | 290 | 210 | 4 | 90 |

| AlSi7Mg0,6 EN AC-42200 A357.0 | T6 | 320 | 240 | 3 | 100 |

| AlSi10Mg(a) EN AC-43000 A359.0 | F | 180 | 90 | 2,5 | 55 |

| T6 | 260 | 220 | 1 | 90 | |

| AlSi8Cu3 EN AC-46200 380.0 | F | 170 | 100 | 1 | 75 |

| AlSi12(b) EN AC-44100 B413.0 | F | 170 | 80 | 5 | 55 |

| AlSi9Cu1Mg EN AC-46400 | F | 170 | 100 | 1 | 75 |

F - as cast

T6 - after annealing and full artificial ageing

We supply this modern material from all commonly used technologies, namely sand casting, precision casting and coquilla. We are also able to provide machining of these alloys, which is more problematic due to the flammability of the filings.

The castings are used wherever the customer appreciates the low weight of this alloy. The most common applications are in automobiles in motorsports, aviation, telescope and camera bodies, optical instruments.

For high voltage applications, we offer both sand casting and precision and die casting. Subsequent machining is also a matter of course. Classically, these alloys are also used in art for casting sculptures.

| ČSN | NAME | DIN | OTHER DESIGNATION |

|---|---|---|---|

| 42 3123 | CuSn12 | 1705 | TIN BRONZE |

| 42 3148 | CuAl10Ni2Mn1 | ALUMINIUM BRONZE | |

| 42 3322 | CuZn31MnAl1 | 1709-73 GCuZn35All | BRASS |

| 42 3303 | CuZn17Si3 | BRASS |

Related articles